|

|

|

Series 22 Dia-Cam Pinch Valve Features

|

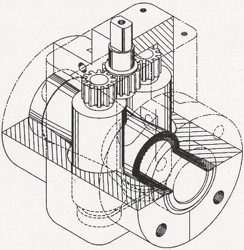

The Series-22 Quarter-Turn Dia-Cam valve is a

high flow capacity pinch valve, designed, for hard-to

handle fluids, especially slurries. The valve interior

consists of a fabric reinforced elastomeric or PTFE-

lined Diaphragm Spool... the only wetted component

of the valve. Two opposing gear-driven cams, contained

in a flanged split vinylester-fiberglass body, act on the

Diaphragm Spool, providing flow control over the entire

90 degrees of valve stem travel. The valve exhibits

negligible pressure drop in the open position and bubble-

tight closure even around solids in the closed position.

Where solids in the slurry make operation of other types

of valves such as ball, plug and butterfly valves , extremely

problematic, the Series-22 Dia-Cam valve is ideally suited

for slurries since there are no "dead zones" in the valve internals.

The valve ID mates to Schedule 40 piping systems and installs

without flange gaskets. The valve is utilized in either ON-OFF

or FLOW CONTROL applications.

|

- Flow-Thru Design

- NO "Dead Zones"

- Only ONE Wetted Part

- No Flange Gaskets Required

- Closes bubble-tight on solids

- On-Off or Flow Control Device

- Lever Detent Assembly for Manual Operation

- Actuated with Any Quarter-Turn Pneumatic or Electric Control Package

- Corrosion-Resistant Vinylester-Fiberglass Construction

- Molded-In Steel Inserts for Flange Bolts and Actuator Mounting Bolts

- Face-to-Face Dimensions per ANSI B16.10, Class 150

- Flange Dimensions per ANSI B16.5, Class 150

- Diaphragm Spool Materials Available in many Standard and Food Grade Elastomers and PTFE-Lined

|

To print out this and other important information, click  |

|

|